***WARNING: This information is specific to Santa Cruz, California!***

After I ruled out

strawbale as a wall material, the remaining materials on my short list were:

The excavation of my neighbor's foundation yielded soil that was promising for rammed earth construction. However, in my opinion, there are 3 primary reasons why rammed earth is unsuitable for my home.

- Like strawbale, rammed earth walls are quite thick (18" minimum). My 1,200 ft2 maximum floorplan area would lose a considerable amount of usable living area to wall thickness.

- Rammed earth construction costs are more than standard construction methods. My limited budget requires that I try to reduce cost wherever possible.

- I live in the strictest zone for earthquake design in the US (seismic zone 4). Building heavy walls that need extensive reinforcement to meet earthquake design requirements does not make sense to me.

This left Rastra and stick-frame. I have one neighbor who built with 10" thick Rastra walls, and another who built with 2X6 stick-frame walls. I like both homes. They are comparable in cost. Stick-frame is the most common residential wall construction method in the US. There are more design specialists and contractors familiar with this type of construction. Rastra is less common, but is similar to

Insulated Concrete Form (ICF) construction. Design specialists and contractors familiar with ICF construction would have the experience necessary to design or build with Rastra.

Advantages of Rastra compared to Stick-frame:

- high resistance to rot and insect infestation should result in long life

- can be used as a stem wall if waterproofed

- insulation R-value is more stable over time than batt insulation

Advantages of Stick-frame compared to Rastra:

- wall is 4" thinner than Rastra resulting in more usable living area

- running electrical and plumbing within the walls is a common process

When I started creating plans in January, 2008, my home design was 1,200 ft

2 on a single story. In May, 2008, I had an

epiphany and changed the design to 1,000 ft

2 with a 200 ft

2 loft. Cindy and I were very enthusiastic about the loft floor plan. The advantages of a single story design compared to a loft are:

- no area "wasted" for a staircase

- easier to grow old in a single story home - no stair climbing

The advantages of a loft design compared to a single story are:

- smaller slab and foundation - reduced cost

- generally requires less energy to heat

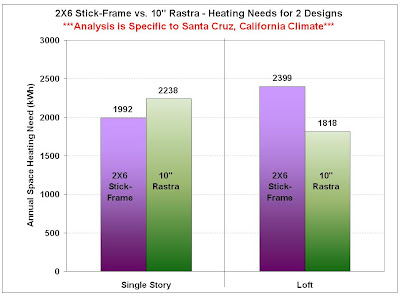

I decided to evaluate the thermal performance of stick-frame and Rastra to determine if the results showed a compelling reason to pick one wall system over the other. I ran an energy analysis using

HEED software to answer this question. I created analytical models of the single story and loft designs. For each type of design (Single Story and Loft), I compared the annual space heating energy need with stick-frame and Rastra walls. I used a free software tool called

OPAQUE to determine the U-factor, time lag and decrement factor variables for both stick-frame and Rastra. These variables are required by HEED to calculate heat loss through the walls. Data for stick-frame wall materials is built into the OPAQUE material database. I obtained data for Rastra wall materials from Rastra president, Karl Holik. The results of the analysis are shown in the graph below. My home design is all electric, so energy units are in killowatt-hours (kWh). You can convert to other energy units using the

online conversion website.

The main conclusion from this analysis is that Stick-Frame and Rastra wall systems perform differently with different home designs. For my single story home design, Rastra walls would require about 15% more heating energy than stick-frame walls to maintain the same interior temperature. However, for my loft design, stick-frame walls would require about 32% more heating energy than Rastra walls. To put these energy needs in perspective, 2 of my PV solar panels will produce the 581 kWh difference between 2X6 stick-frame and 10" Rastra walls for the loft design. Even though the heating energy required for any of these designs is relatively small compared to an average American home, I'm happy to know that my Rastra loft is the best performing design.

The moral of the story is than an energy analysis of your home design can predict your energy needs. The analysis may also help if you are undecided on your wall system. Thanks for reading. As always, your comments are appreciated.

Thanks for reading. I appreciate your comments.

Thanks for reading. I appreciate your comments.